- Home

- Products

- Grinder Machine

- WF Series Coarse Crusher

- F Series Universal Crusher

- FU Series Universal Grinder Unit

- WFU Dry And Wet Dual-purpose Grinder

- WFJ Series Air Classifier Mill

- LYCM Series Colloid mill

- WFM Series Ultra Micro Vibration Mill

- LYHM Series Hammer Mill Unit

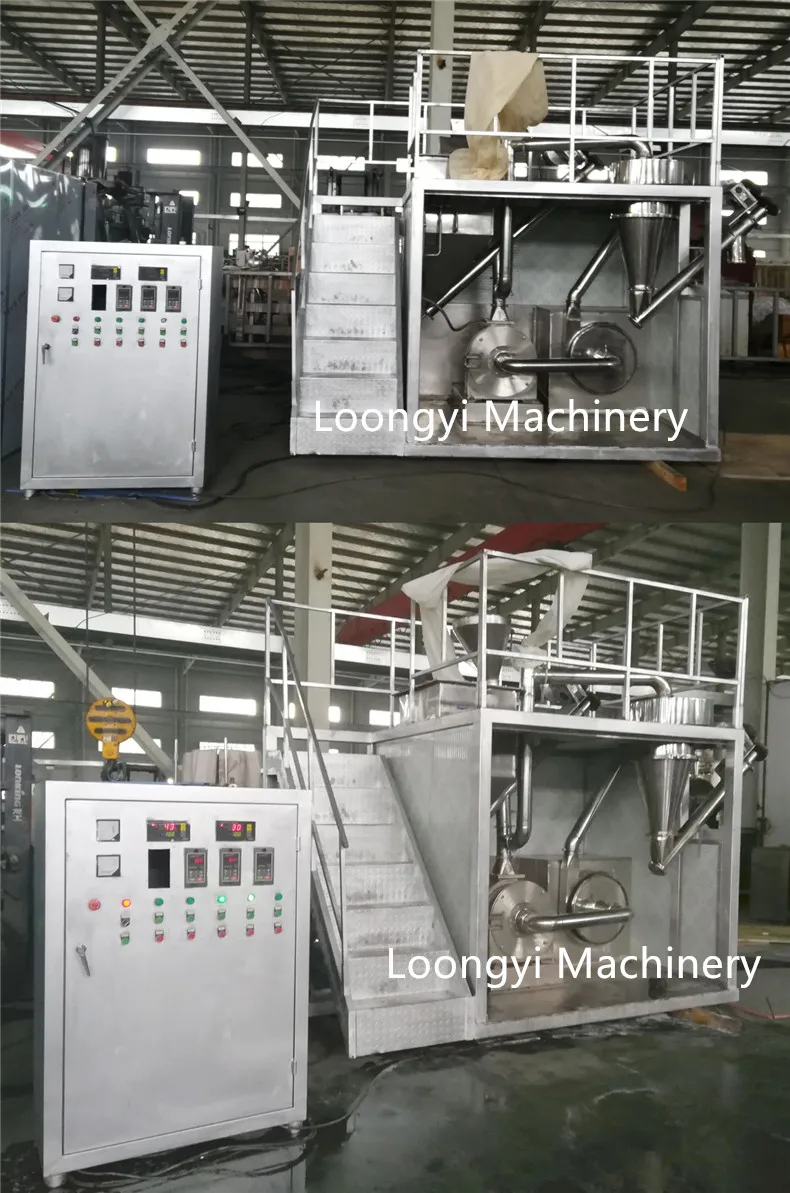

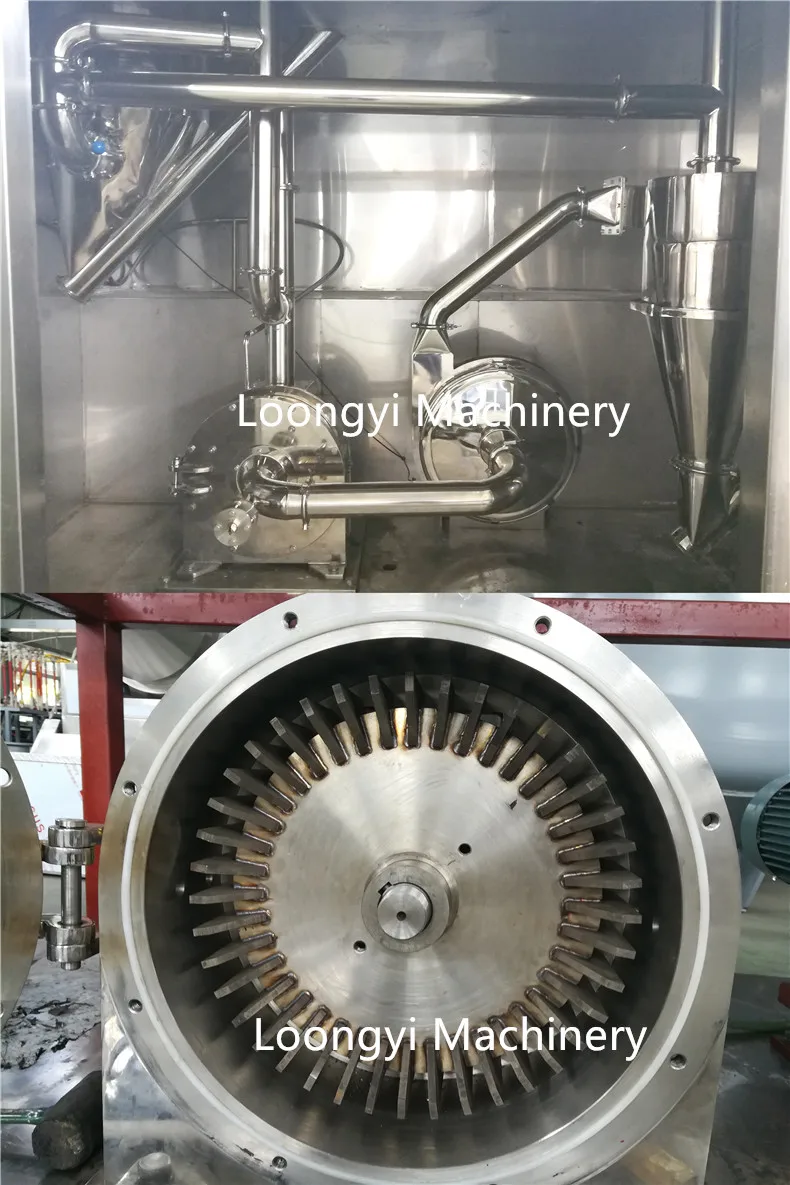

- LYPM Series Pin Mill

- LYFM Series High Efficient Mill (Fitz Mill)

- LYCM Series Liquid Nitrogen Cryogenic Mill

- LYRM Series Oil Materials Roller Mill

- Mixer Machine

- CH Series Trough Type Mixer

- WLDH Series Horizontal Ribbon Mixer

- WZ Series Double Shaft Paddle Mixer

- LTD Series Plow Blade Type Mixer

- WH Series Double Spiral Mixer

- W Series Double Cone Mixer

- LYV Series V Type mixer

- FH Series Square Cone Mixer

- EYH Two-dimensional Motion Mixer

- SYH Three-dimensional Swing Mixer

- Granulator Machine

- Sifter Machine

- Dryer Machine

- Feeding Machine

- Packing Machine

- Slicer Machine

- GR Series Ginger Slicer Shredder Machine

- GR Series Vegetable Fruit Frozen Meat Dicer Machine

- GR-3300 Electric Fruit and Vegetable Slicer

- GR Series Fruit and Vegetable Slicer Cutter Machine

- GR Series Electric Automatic Garlic Slicer

- SD-1039 Manual Slicer Machine

- GR-5035 banana slicer machine

- K2139AL potato chips slicer machine

- K6238 vegetable cutter machine

- SP-230A slicing machine

- SD-2139AL Electric Slicer

- GR-K6238AL Horizontal Multifunctional Vegetable Slicer

- SD-3169XL 500KG/H Slicer Machine

- GR series vegetable and fruit slicer machine

- GR-Roll and french fry machine

- K5138AL-Vegetable fruit slicing

- SD-3139AL - Vegetable fruit slicing

- SP-280D Electric Dicer Machine

- SP-220 Vegetable Slicer Shredder Machine

- GR-850 Double Head Multifunctional Cutter

- LYMS-1 Single Head Slicer Machine

- LYBS Series Belt Slicer Machine

- LYSR Series Mash Machine

- Cleaning Machine

- Grinder Machine

- News

- About us

- Contact

- Home

- Products

- Grinder Machine

- WF Series Coarse Crusher

- F Series Universal Crusher

- FU Series Universal Grinder Unit

- WFU Dry And Wet Dual-purpose Grinder

- WFJ Series Air Classifier Mill

- LYCM Series Colloid mill

- WFM Series Ultra Micro Vibration Mill

- LYHM Series Hammer Mill Unit

- LYPM Series Pin Mill

- LYFM Series High Efficient Mill (Fitz Mill)

- LYCM Series Liquid Nitrogen Cryogenic Mill

- LYRM Series Oil Materials Roller Mill

- Mixer Machine

- CH Series Trough Type Mixer

- WLDH Series Horizontal Ribbon Mixer

- WZ Series Double Shaft Paddle Mixer

- LTD Series Plow Blade Type Mixer

- WH Series Double Spiral Mixer

- W Series Double Cone Mixer

- LYV Series V Type mixer

- FH Series Square Cone Mixer

- EYH Two-dimensional Motion Mixer

- SYH Three-dimensional Swing Mixer

- Granulator Machine

- Sifter Machine

- Dryer Machine

- Feeding Machine

- Packing Machine

- Slicer Machine

- GR Series Ginger Slicer Shredder Machine

- GR Series Vegetable Fruit Frozen Meat Dicer Machine

- GR-3300 Electric Fruit and Vegetable Slicer

- GR Series Fruit and Vegetable Slicer Cutter Machine

- GR Series Electric Automatic Garlic Slicer

- SD-1039 Manual Slicer Machine

- GR-5035 banana slicer machine

- K2139AL potato chips slicer machine

- K6238 vegetable cutter machine

- SP-230A slicing machine

- SD-2139AL Electric Slicer

- GR-K6238AL Horizontal Multifunctional Vegetable Slicer

- SD-3169XL 500KG/H Slicer Machine

- GR series vegetable and fruit slicer machine

- GR-Roll and french fry machine

- K5138AL-Vegetable fruit slicing

- SD-3139AL - Vegetable fruit slicing

- SP-280D Electric Dicer Machine

- SP-220 Vegetable Slicer Shredder Machine

- GR-850 Double Head Multifunctional Cutter

- LYMS-1 Single Head Slicer Machine

- LYBS Series Belt Slicer Machine

- LYSR Series Mash Machine

- Cleaning Machine

- Grinder Machine

- News

- About us

- Contact